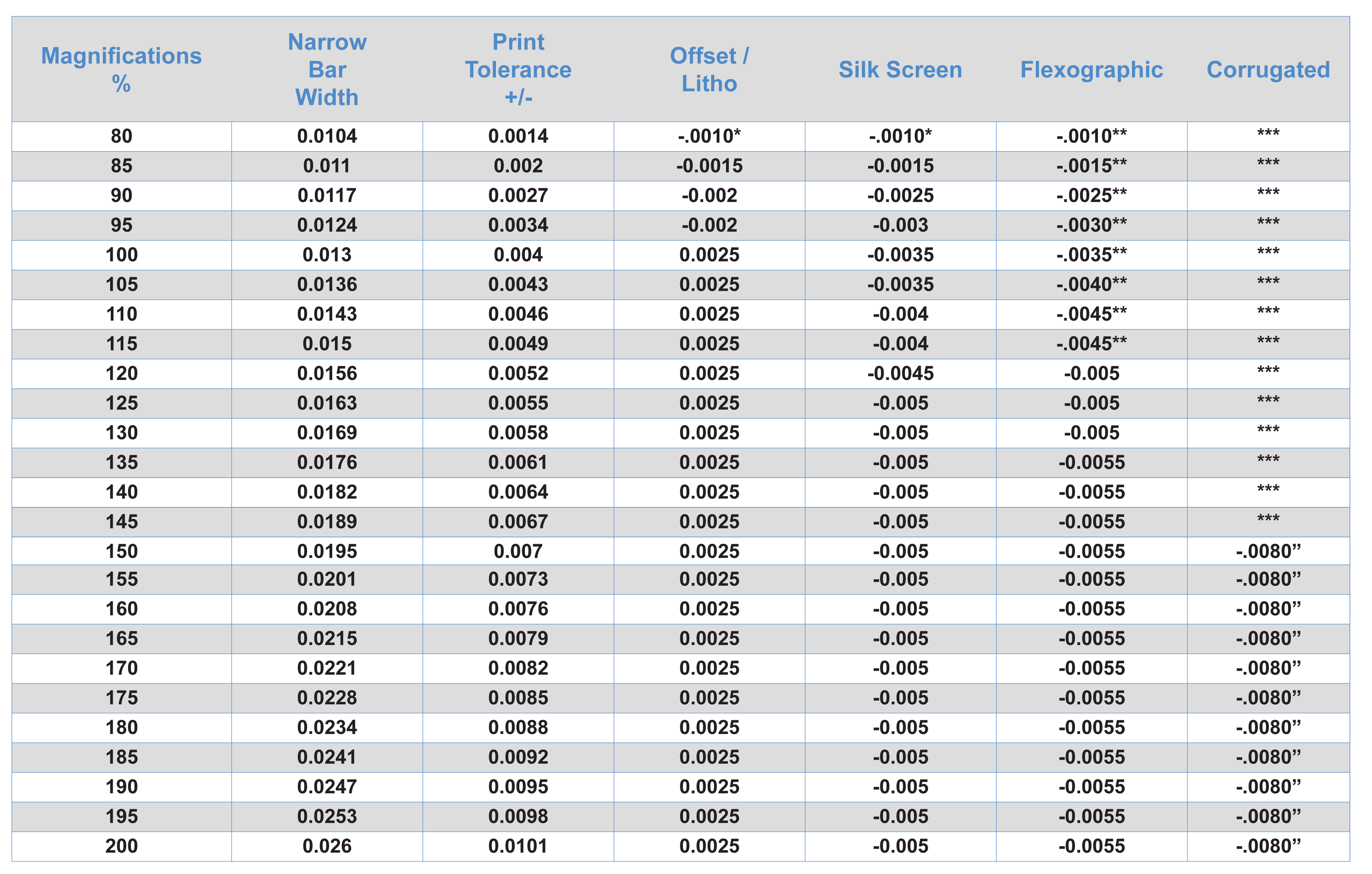

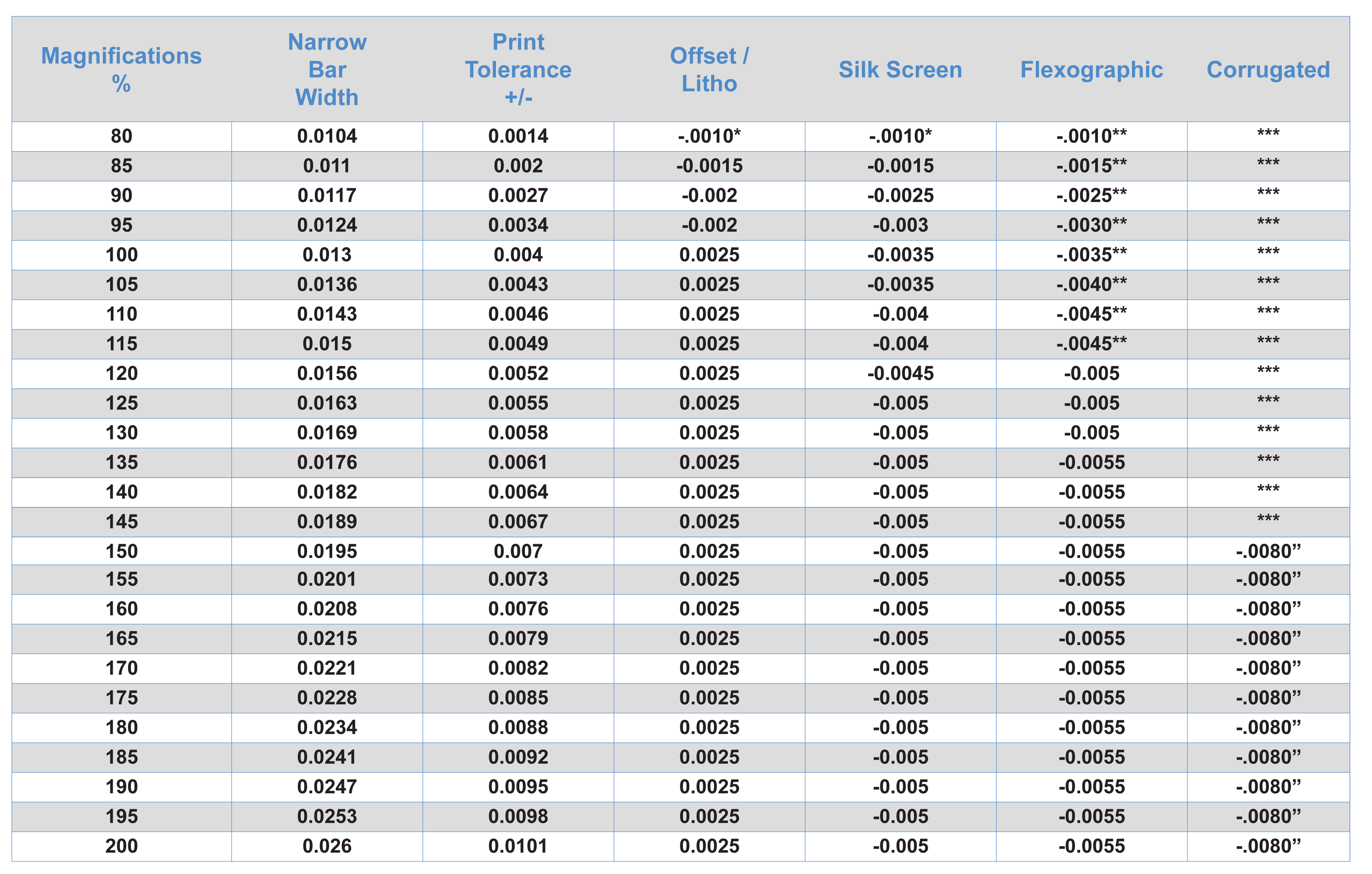

Tolerance Table In Inches

General ISO Geometrical Tolerances Per. ISO 2768 | The following are general geometrical tolerances per. ISO 2768 for the following: - Linear Dimensions

- External Radius and Chamfer Heights

- Straightness and Flatness

- Perpendicularity

- Symmetry

- Runout

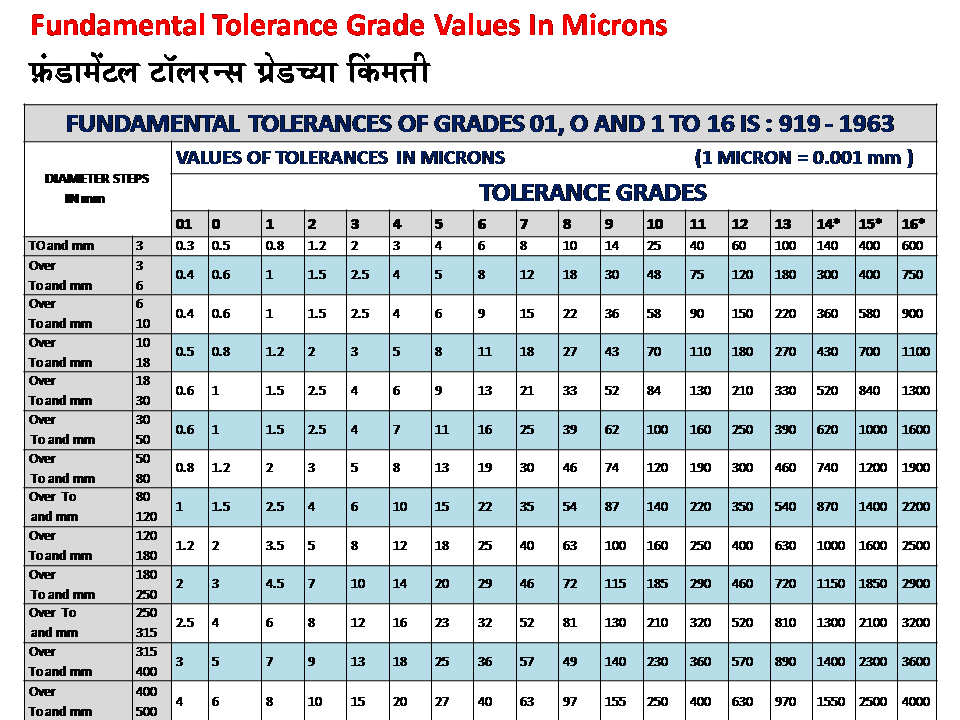

Related Mechanical Tolerance Design Data Variations on dimensions without tolerance values are according to ' ISO 2768'. All tolerance limits are given in mm. ISO 2768 and derivative geometrical tolerance standards are intendedto simplify drawing specifications for mechanical tolerances. ISO 2768 is mainly for parts that are manufactured by way of machining or removal of materials. Linear Dimensions: | Permissible deviations in mm for ranges in nominal lengths | f (fine) | Tolerance class designation (description) | v (very coarse) | | m (medium) | c (coarse) | | 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | - |

|---|

| over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 | | over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 | | over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 | | over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 | | over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 | | over 1000 up to 2000 | ±0.5 | ±1.2 | ±3.0 | ±6.0 | | over 2000 up to 4000 | - | ±2.0 | ±4.0 | ±8.0 |

|---|

External Radius and Chamfer Heights | Permissible deviations in mm for ranges in nominal lengths | f (fine) | Tolerance class designation (description) | v (very coarse) | | m (middle) | c (coarse) | | 0.5 up to 3 | ±0.2 | ±0.2 | ±0.4 | ±0.4 | | over 3 up to 6 | ±0.5 | ±0.5 | ±1.0 | ±1.0 | | over 6 | ±1.0 | ±1.0 | ±2.0 | ±2.0 |

Angular Dimensions | Permissible deviations in degrees and minutes for ranges in nominal lengths | f (fine) | Tolerance class designation (description) | v (very coarse) | | m (middle) | c (coarse) | | up to 10 | ±1º | ±1º | ±1º30' | ±3º | | over 10 up to 50 | ±0º30' | ±0º30' | ±1º | ±2º | | over 50 up to 120 | ±0º20' | ±0º20' | ±0º30' | ±1º | | over 120 up to 400 | ±0º10' | ±0º10' | ±0º15' | ±0º30' | | over 400 | ±0º5' | ±0º5' | ±0º10' | ±0º20' |

Straightness and Flatness | Ranges in nominal lengths in mm | Tolerance class | | H | K | L | | up to 10 | 0.02 | 0.05 | 0.1 | | over 10 up to 30 | 0.05 | 0.1 | 0.2 | | over 30 up to 100 | 0.1 | 0.2 | 0.4 | | over 100 up to 300 | 0.2 | 0.4 | 0.8 | | over 300 up to 1000 | 0.3 | 0.6 | 1.2 | | over 1000 up to 3000 | 0.4 | 0.8 | 1.6 |

Perpendicularity | Ranges in nominal lengths in mm | Tolerance class | | H | K | L | | up to 100 | 0.2 | 0.4 | 0.6 | | over 100 up to 300 | 0.3 | 0.6 | 1 | | over 300 up to 1000 | 0.4 | 0.8 | 1.5 | | over 1000 up to 3000 | 0.5 | 0.8 | 2 |

Symmetry (Position for ISO G&T Standard not-ASME or ANSI GD&T) | Ranges in nominal lengths in mm | Tolerance class | | H | K | L | | up to 100 | 0.5 | 0.6 | 0.6 | | over 100 up to 300 | 0.5 | 0.6 | 1 | | over 300 up to 1000 | 0.5 | 0.8 | 1.5 | | over 1000 up to 3000 | 0.5 | 1 | 2 |

Run-Out | Tolerance class | | H | K | L | | 0.1 | 0.2 | 0.5 |

Related Resources: - Online GD&T Fundamentals

© Copyright 2000 - 2021, by Engineers Edge, LLC www.engineersedge.com

All rights reserved

Disclaimer | Feedback

Advertising | Contact | Privacy Policy Date/Time:

|

| Membership

Register | Login | Home

Engineering Book Store

Engineering Forum

Excel App. Downloads

Online Books & Manuals

Engineering News

Engineering Videos

Engineering Calculators

Engineering Toolbox

GD&T Training Geometric Dimensioning Tolerancing

DFM DFA Training

Training Online Engineering

Advertising Center

|

|

|

Tolerance Table In Inches

The tolerance symbols that we use are in line with ISO 492 and ISO 199 and are explained in the previously mentioned tolerance tables and in table 12. The symbols normally refer to dimensional tolerances, only Kia, Kea, Sd, SD, Sia and Sea refer to geometrical tolerances. Glass table tops enhance the interior effortlessly. Place your glass table top online orders at Glass Genius for the best quality custom glass table tops. 3/16″ thick glass works well for a glass table top cover that rests on a table top or on lighter duty tables where the glass fits into an outside frame. 1/4” thick glass is a good thickness for heavier duty glass table top covers, standard duty tables with outside frames or smaller tables with lighter duty uses.